Premium Used HTST Pasteurization Systems

- About

- FAQs

- ←

- →

Frequently Asked Questions

High-Temperature Short-Time (HTST) equipment is an important type of food processing equipment used in the food and beverage industry. This pasteurizer equipment works by heating a batch of food and beverage products to high temperatures for a short period of time. This quick heat treatment for the required length of time destroys pathogenic microorganisms, ensuring the sanitary standards of food products.

HTST batch pasteurizers are a crucial part of the food industry and are used in a variety of food and beverage applications. It's commonly used to pasteurize milk products, juice, and other beverages, as well as to process canned items such as soups, sauces, and jams in a short time. In addition, pasteurizer equipment is used in the cheese industry to denature proteins, which helps improve the taste, texture, and package shelf life of dairy products.

HTST pasteurizer equipment works by quickly heating the food or beverage to a high temperature using either hot water or steam. This quick heating and cooling process kills any harmful bacteria, viruses, and other pathogens, ensuring the safety and quality of food products. The high temperature of the pasteurizer also helps denature proteins and preserve food, making them safe and shelf-stable.

In general, HTST equipment is composed of a vat pasteurizer and a series of heat exchangers, pumps, valves, and other components. The heat exchangers are used to heat food products to the required temperature for the proper time and then cool them quickly. The pumps and valves help regulate the flow of the product through the system. The HTST process is generally automated, allowing for a high degree of control over the process and ensuring consistent product quality. An HTST system is an important part of the food and beverage industry, offering a safe and efficient way to pasteurize raw milk and other food and beverage products. With the quick and efficient heat treatment provided by HTST equipment, food and beverage companies can ensure the safety and quality of their products to meet industry and Food and Drug Administration standards.

If you're looking for quality, used equipment, there are several different types of HTST pasteurizer equipment available. The most common type of HTST system is a plate pasteurizer. This equipment is a plate heat exchanger system that's heated to a specific temperature and then pressurizes a pasteurized product as it passes through the plates.

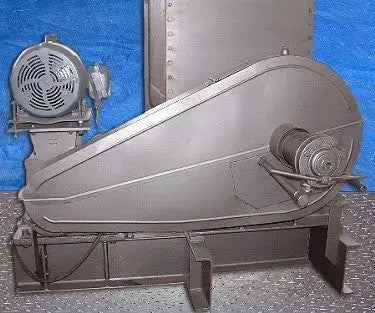

A tubular pasteurization system is a batch pasteurizer made up of long, stainless steel holding tubes that are heated to the desired temperature. The product is then forced through the tubes, where it's pasteurized. Finally, a rotary pasteurization system is made up of a rotating drum that's heated to the desired temperature.

Top Sellers

View all